In the use of water-based inks, there are usually problems such as hue inaccuracy, too fast or too slow drying, blurred outlines, difficulty in registering, ink blistering, paste sticking, and blotting. The main reasons are as follows: : 1. Control of PH value: PH value is the key to determine the success or failure of water-based ink manufacturing and its printing suitability technology. When using water-based inks, it is necessary to accurately control the viscosity and pH. Its pH should be controlled between 8.0 and 9.5. If the pH of the water-based ink is too high, too much alkali will affect the drying speed of the ink, and the back side will be dirty and the water resistance will be poor. If the pH is too low, the alkalinity will be too weak, the viscosity of the ink will increase, and the drying speed will be faster. It is easy to cause defects such as dirty plate, paste and foaming.

Polar Fleece Jacket With Hood,Polar Fleece Pyjama,Men'S Polar Fleece Jacket,Boys Polar Fleece Jacket With Pocket Jinan Topline Trading Co., Ltd. , https://www.jinantopline.com

The pH of the aqueous ink is mainly maintained by the amine compound. During the printing process, as the amine in the binder is continuously volatilized, the pH value will decrease, which will affect the printing quality. In the actual control, on the one hand, it is necessary to avoid the leakage of amine substances as much as possible, such as covering the upper cover of the ink tank; on the other hand, it is necessary to add a stabilizer to the ink tank regularly and quantitatively. When the pH value is low, a pH stabilizer or a small amount of alkaline substance may be added; when the pH is high, a solvent or a diluent may be added for polarity dilution.

2. Temperature and humidity control: The temperature and humidity of the printing workshop are closely related to the drying and color of the water-based ink printing products. When the relative humidity reaches 95% and 65%, the drying time is almost twice as high. At the same time, the dry humidity of the substrate itself will directly affect the drying time of the printed matter.

3. Ventilation degree and printing method: Since oxygen or blowing is a factor that promotes the formation of oxidative polymerization of aqueous ink and the formation of strong ink film, the degree of ventilation in the printing workshop and the way of printing the printed matter will also affect the drying speed of the ink.

4. Printing material: The PH value of the printing material also has an effect on the drying and gloss of the aqueous ink. Water-based inks are affected by the pH of the printing paper when it is printed on the paper surface. When the acidity of the paper is high, the coupling agent as a drier in the aqueous ink does not work, the alkali in the aqueous ink is neutralized, and the dryness is advanced; when the paper is alkaline, the aqueous ink dries slowly, and sometimes the aqueous ink is limited. Completely resistant to water.

Zhongshan Zhongyi Ink Coating Co., Ltd. is located in Port Town, Zhongshan City, Guangdong Province. It is one of the top ten brand manufacturers and suppliers of environmentally friendly silk screen printing ink industry in China. It is a national investment agent and joins cooperation. It specializes in producing and supplying uv printing ink and pvc screen printing ink. Pet water-based offset printing glass ink, printing materials, color crystal four-color printing ink, ink additives, printing equipment, plate making materials.

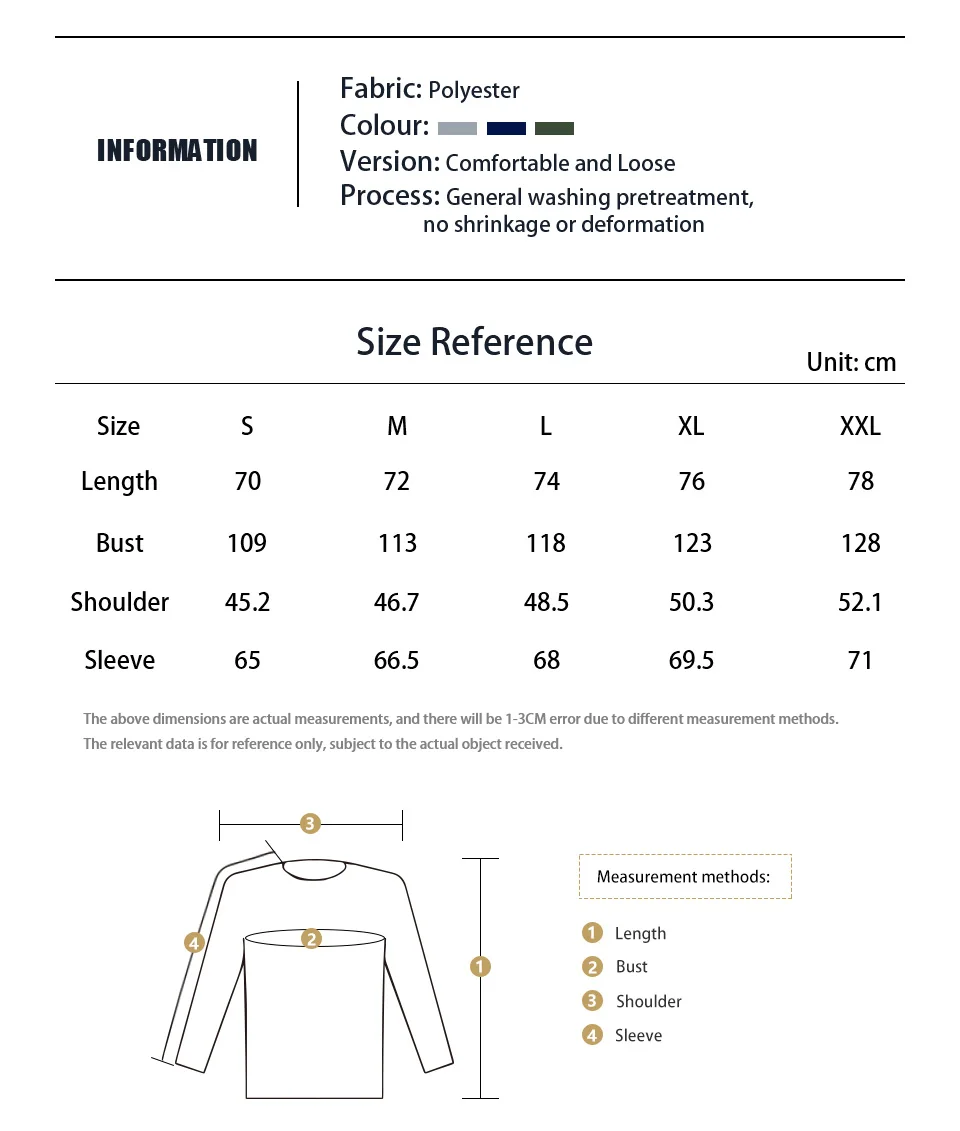

Product Specification

Item

Men's Full-Zip Polar Fleece Jacket Polar Winter Outdoor Coat

Style#

BG6815

Fabric

100% polyester fleece fabric

Color

Gray, Navy,Green

Size

S-4XL

Packing Details

1pc/polybag, 20 pcs/ctn

MEAS

50cm×40cm×46cm

G.W./N.W.

12kg/11kg

MOQ

1 pc

Delivery Time

3-5 workingdays for instock sample

Size Information

Model Show

Recommend Products